Uvavanyo olusebenzayo lwezakhono

Uvavanyo olubanzi olusetyenziswa kulo lonke uphuhliso lwemveliso entsha lugcina imali yomthengi ngelixa kuncitshiswa ixesha lokwenziwa kwemveliso. Kwinqanaba lokuqala, uvavanyo lwe-circuit, ukuhlolwa kwe-automated optical (AOI) kunye nokuhlolwa kwe-Agilent 5DX kunika ingxelo ebalulekileyo eququzelela uhlengahlengiso ngexesha. Emva koko uvavanyo olusebenzayo kunye nesicelo lwenziwa kwiinkcukacha zomthengi ngamnye ngaphambi kokuba uvavanyo olungqongqo lwexinzelelo lokusingqongileyo luqinisekise ukuthembeka kwemveliso. Xa kuziwa ekuziseni imveliso entsha, i-POE yobuchule obusebenzayo kunye nokuvavanya iqinisekisa ukuba iyakha ngokufanelekileyo okokuqala, kunye nokubonelela ngesisombululo esidlula ukulindela.

Uvavanyo olusebenzayo:

Inyathelo lokugqibela lokuVelisa

Uvavanyo olusebenzayo (FCT) lusetyenziswa njengenyathelo lokugqibela lokuvelisa. Ibonelela ngokupasa/ukungaphumeleli ukuzimisela kwiiPCB ezigqityiweyo phambi kokuba zithunyelwe. Injongo ye-FCT ekuveliseni kukuqinisekisa ukuba i-hardware yemveliso ayinaziphene ezinokuthi, kungenjalo, zichaphazele kakubi ukusebenza kwemveliso kwisicelo senkqubo.

Ngokufutshane, i-FCT iqinisekisa ukusebenza kwe-PCB kunye nokuziphatha kwayo. Kubalulekile ukugxininisa ukuba iimfuno zovavanyo olusebenzayo, uphuhliso lwalo, kunye neenkqubo ziyahluka ngokubanzi ukusuka kwi-PCB ukuya kwi-PCB kunye nenkqubo ukuya kwisistim.

Abavavanyi abasebenzayo bajongana ne-PCB phantsi kovavanyo ngesidibanisi somphetho okanye indawo yovavanyo. Olu vavanyo lulinganisa indawo yokugqibela yombane apho iPCB iya kusetyenziswa khona.

Olona hlobo luqhelekileyo lovavanyo olusebenzayo luqinisekisa nje ukuba iPCB isebenza ngokufanelekileyo. Uvavanyo oluntsonkothileyo olusebenzayo lubandakanya ukukhwela ibhayisekile kwi-PCB ngoluhlu olupheleleyo lweemvavanyo zokusebenza.

Izinto eziluncedo kuMthengi kuVavanyo oluSebenzayo:

● Uvavanyo olusebenzayo lulinganisa imeko-bume yokusebenza yemveliso ephantsi kovavanyo ngaloo ndlela kuncitshiswa iindleko ezixabisa kakhulu ukuze umthengi abonelele ngezona zixhobo zovavanyo.

● Iphelisa imfuneko yovavanyo lwenkqubo ebiza kakhulu kwezinye iimeko, egcina i-OEM ixesha elininzi kunye nezibonelelo zemali.

● Iyakwazi ukujonga ukusebenza kwemveliso naphi na ukusuka kwi-50% ukuya kwi-100% yemveliso ethunyelwayo ngaloo ndlela inciphisa ixesha kunye nomgudu kwi-OEM ukuyijonga kunye nokuyilungisa.

● Iinjineli zovavanyo ezilumkileyo zinokukhupha eyona mveliso kuvavanyo olusebenzayo ngokwenza ukuba ibe sesona sixhobo sisebenzayo sifutshane kuvavanyo lwesixokelelwano.

● Uvavanyo olusebenzayo luphucula ezinye iintlobo zovavanyo olufana ne-ICT kunye novavanyo lwe-flying probe, lwenza imveliso yomelele ngakumbi kwaye ingabi nazimpazamo.

Uvavanyo olusebenzayo lulinganisa okanye lulinganisa indawo yokusebenza yemveliso ukujonga ukusebenza kwayo okuchanekileyo. Imeko-bume ibandakanya nasiphi na isixhobo esinxibelelana nesixhobo phantsi kovavanyo (DUT), umzekelo, umbane we-DUT okanye ukulayisha inkqubo eyimfuneko ukwenza i-DUT isebenze kakuhle.

I-PCB iphantsi kolandelelwano lwemiqondiso kunye nonikezelo lwamandla. Iimpendulo zibekwe esweni kumanqaku athile ukuqinisekisa ukuba ukusebenza kuchanekile. Uvavanyo ludla ngokuqhutywa ngokwenjineli yovavanyo ye-OEM, echaza iinkcukacha kunye neenkqubo zovavanyo. Olu vavanyo lungcono ekufumaneni amaxabiso ecandelo elingalunganga, ukungaphumeleli kokusebenza kunye nokungaphumeleli kweparametric.

Isoftware yovavanyo, ngamanye amaxesha ebizwa ngokuba yi-firmware, ivumela abaqhubi bomgca wemveliso ukuba benze uvavanyo olusebenzayo ngendlela ezenzekelayo ngekhompyuter. Ukwenza oku, isofthiwe inxibelelana nezixhobo zangaphandle ezicwangcisiweyo njenge-digital multi-meter, iibhodi ze-I / O, izibuko zonxibelelwano. Isoftware edityaniswe nokudibanisa izixhobo kunye ne-DUT yenza kube lula ukwenza i-FCT.

Thembela kuMboneleli we-EMS we-Savvy

Ii-OEM ezihlakaniphile zithembele kumnikezeli we-EMS ohloniphekileyo ukuba abandakanye uvavanyo njengenxalenye yoyilo lwemveliso kunye nendibano. Inkampani ye-EMS yongeza ukuguquguquka okubonakalayo kwindawo yokugcina iteknoloji ye-OEM. Umnikezeli we-EMS onamava uyila kwaye ahlanganise uluhlu olubanzi lweemveliso zePCB kwiqela elilinganayo labathengi. Ke ngoko, iqokelela uluhlu olubanzi kakhulu lolwazi, amava kunye nobuchule kunabathengi babo be-OEM.

Abathengi be-OEM banokuzuza kakhulu ngokusebenza nomboneleli we-EMS onolwazi. Esona sizathu siphambili ngumboneleli we-EMS onamava kunye ne-savvy utsala kwisiseko sakhe samava kwaye wenza iziphakamiso ezixabisekileyo ezinxulumene neendlela ezahlukeneyo zokuthembeka kunye nemigangatho. Ngenxa yoko, umboneleli we-EMS mhlawumbi ukwindawo efanelekileyo yokunceda i-OEM ivavanye iinketho zayo zovavanyo kwaye icebise ezona ndlela zovavanyo zingcono zokuphucula ukusebenza kwemveliso, ukwenziwa, umgangatho, ukuthembeka, kunye neyona nto ibalulekileyo, ixabiso.

I-Flying head probe/uvavanyo olungaphantsi kwe-fixture

I-AXI - i-2D kunye ne-3D yokuhlolwa kwe-X-ray ngokuzenzekelayo

I-AOI – uhlolo oluzenzekelayo lokubona

I-ICT - uvavanyo lwe-in-circuit

I-ESS - ukuhlolwa koxinzelelo lwendalo

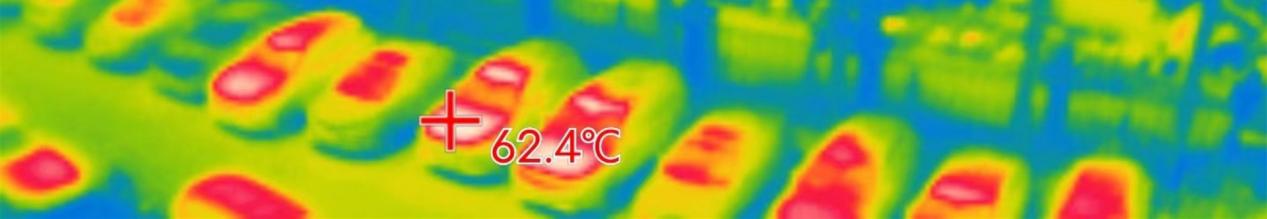

I-EVT - uvavanyo lokuqinisekiswa kokusingqongileyo

I-FT - uvavanyo olusebenzayo kunye nenkqubo

CTO – qwalasela-uku-odola

Uhlalutyo lokuxilonga kunye nokungaphumeleli

PCBA Manufacturing & Test

Ukwenziwa kwemveliso yethu esekwe kwiPCBA iphatha uluhlu olubanzi lweendibano, ukusuka kwiindibano zePCB enye ukuya kwiiPCBA ezidityaniswe kwiibhokisi zokwakhiwa kwebhokisi.

SMT, PTH, iteknoloji exubeneyo

Inowuti entle kakhulu, QFP, BGA, μBGA, CBGA

Indibano yeSMT ekwinqanaba eliphezulu

Ufakelo oluzenzekelayo lwe-PTH (i-axial, i-radial, idiphu)

Akukho ukusetyenzwa okucocekileyo, okunamanzi kunye nelothe

Ubuchule bokwenza iRF

Isakhono senkqubo yeperipheral

Iinqwelomoya zePressfit ngasemva kunye neenqwelomoya eziphakathi

Ukucwangcisa isixhobo

Ukwaleka ngokusesikweni okuzenzekelayo

Iinkonzo zethu zobuNjineli beXabiso (VES)

Iinkonzo zobunjineli zexabiso le-POE zenza ukuba abathengi bethu baphucule ukwenziwa kwemveliso kunye nokusebenza komgangatho. Sijolisa kuwo wonke umba woyilo kunye neenkqubo zokuvelisa - ukuvavanya zonke iimpembelelo kwiindleko, umsebenzi, ishedyuli yenkqubo kunye neemfuno zizonke.

I-ICT yenza uVavanyo oluBanzi

Kuvavanyo lwesekethe (ICT) isetyenziswa ngokwesiko kwiimveliso ezivuthiweyo, ngakumbi kwimveliso ye-subcontract. Isebenzisa ibhedi yovavanyo lwezikhonkwane ukufikelela kwiindawo ezininzi zovavanyo kwicala elisezantsi lePCB. Ngeendawo ezaneleyo zokufikelela, i-ICT inokudlulisa imiqondiso yovavanyo ngaphakathi nangaphandle kwe-PCB ngesantya esiphezulu ukwenza uvavanyo lwamacandelo kunye neesekethe.

Umandlalo ovavanya iinzipho yinto eqhelekileyo yovavanyo lwe-elektroniki. Inezikhonkwane ezininzi ezifakwe emingxunyeni, ezilungelelaniswe kusetyenziswa izikhonkwane zesixhobo ukwenza

ukunxibelelana namanqaku ovavanyo kwibhodi yesekethe eprintiweyo kwaye idityaniswe neyunithi yokulinganisa ngeengcingo. Ezi zixhobo ziqulathe uluhlu lwezikhonkwane ze-pogo ezincinci, ezilayishwe entwasahlobo ezenza uqhagamshelwano nenodi enye kumjikelezo wesixhobo esiphantsi kovavanyo (DUT).

Ngokucinezela i-DUT phantsi kwibhedi yezikhonkwane, uqhagamshelwano oluthembekileyo lunokwenziwa ngokukhawuleza ngamakhulu kwaye kwezinye iimeko amawakawaka amanqaku ovavanyo lomntu ngamnye ngaphakathi kwesekethe ye-DUT. Izixhobo eziye zavavanywa kumandlalo womvavanyi wezikhonkwane zingabonisa uphawu oluncinane okanye idimple ephuma kwiincam ezibukhali zezikhonkwane zepogo ezisetyenziswe kwifixture.

Kuthatha iiveki ezimbalwa ukwenza i-ICT fixture kwaye yenze inkqubo yayo. Isixhobo sinokuba sivacuum okanye sicinezele phantsi. Izixhobo zokufunxa zinika umqondiso ongcono wokufunda ngokuchasene nohlobo lokucofa. Kwelinye icala, izixhobo zokufunxa zibiza imali eninzi ngenxa yokuntsonkotha kwazo okuphezulu. Ibhedi yezikhonkwane okanye i-in-circuit tester iyona nto ixhaphakileyo kwaye ithandwa kakhulu kwindawo yokuvelisa isivumelwano.

I-ICT ibonelela umthengi we-OEM ngezibonelelo ezinje:

● Nangona kufuneka ukulungiswa okunexabiso eliphezulu, i-ICT ibandakanya uvavanyo lwe-100% ukwenzela ukuba kubonwe zonke iifutshane zamandla kunye naphantsi komhlaba.

● Uvavanyo lwe-ICT luxhobisa uvavanyo kwaye luphelise ulungiso lweempazamo kubathengi phantse ukuya ku-ZERO.

● I-ICT ayithathi xesha lide kakhulu ukwenza, umzekelo ukuba i-Flying probe ithatha imizuzu engama-20 okanye njalo, i-ICT ngexesha elinye inokuthatha umzuzu okanye njalo.

● Utshekisha uze ubhaqe iibhulukhwe ezimfutshane, ezivulayo, ezishiyiweyo, iikhomponenti zexabiso elingelilo, iipolarities ezingalunganga, iikhomponenti ezineziphene kunye nokuvuza okukhoyo kwiisekethe.

● Uvavanyo oluthembeke kakhulu nolubanzi olubamba zonke iziphene zokuvelisa, iziphene kuyilo, kunye neziphene.

● Iqonga lovavanyo liyafumaneka kwi-Windows kunye ne-UNIX, ngaloo ndlela iyenza ifikeleleke ngokubanzi kwiimfuno ezininzi zovavanyo.

● Ujongano lophuhliso lovavanyo kunye nendawo yokusebenza isekelwe kwimigangatho yenkqubo evulekileyo kunye nokuhlanganiswa ngokukhawuleza kwiinkqubo ezikhoyo zomthengi we-OEM.

I-ICT lolona vavanyo ludinayo, lunzima, nolubiza imali eninzi. Nangona kunjalo, i-ICT ifanelekile kwiimveliso ezikhulileyo ezifuna ukuveliswa komthamo. Iqhuba umqondiso wamandla ukujonga amanqanaba ombane kunye nemilinganiselo yokuchasa kwiindawo ezahlukeneyo zebhodi. I-ICT igqwesile ekuboneni ukungaphumeleli kweparametric, iimpazamo ezinxulumene noyilo kunye nokusilela kwecandelo.

Ixesha lokuposa: Jul-19-2021